PRODUCTS AND SOLUTIONS

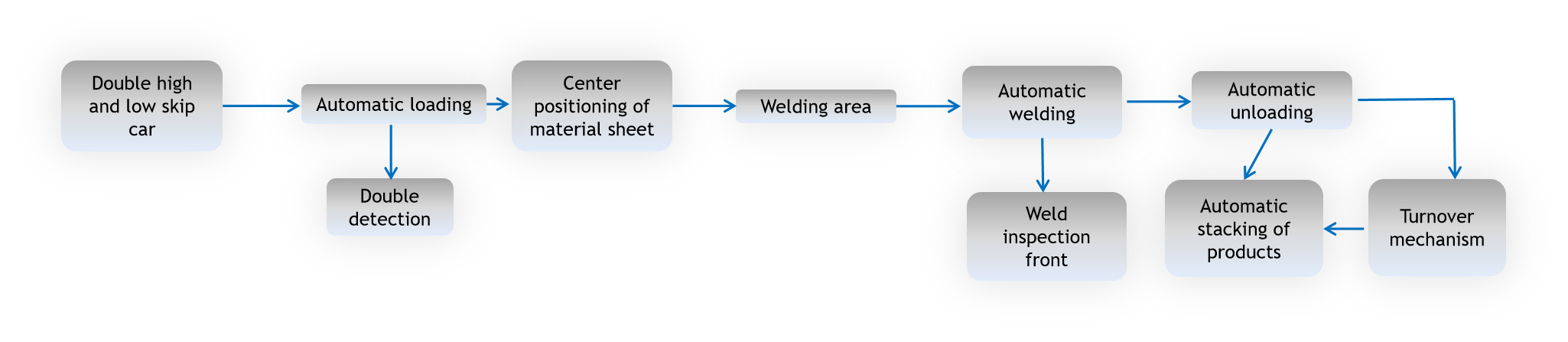

It ensure that the skylight and door knocker of linear weld line are processed. economically and efficiently. The system can meet the welding requirements of different skylights and door rings with transverse welds. The whole production line is fully automatic, the personnel only need timing refueling, and the switching of loading and unloading does not affect the production of equipment.

The production line is fully automatic loading and unloading, high and low skip car is used in the material preparation area, so that there is no need to stop the line when preparing materials.

Automatic positioning module, adapt to the same type of different size of skylight welding requirements.

The numerical control system realizes the operation control of welding seam trajectory interpolation and realizes high-precision welding.

Weld joint tracking detection and post-welding quality detection, judge welding quality online real-time.

Double-station reservation welding real-time , improve the laser vibration rate.

Double material detection system to avoid double material welding.

Real-time ethernet communication between CNC and PLC, sharing shaft position and working state.

Laser welding improves material utilization rate and reduces raw material cost.