PRODUCTS AND SOLUTIONS

Location:Home > Product and Solution>Automatic assembly line

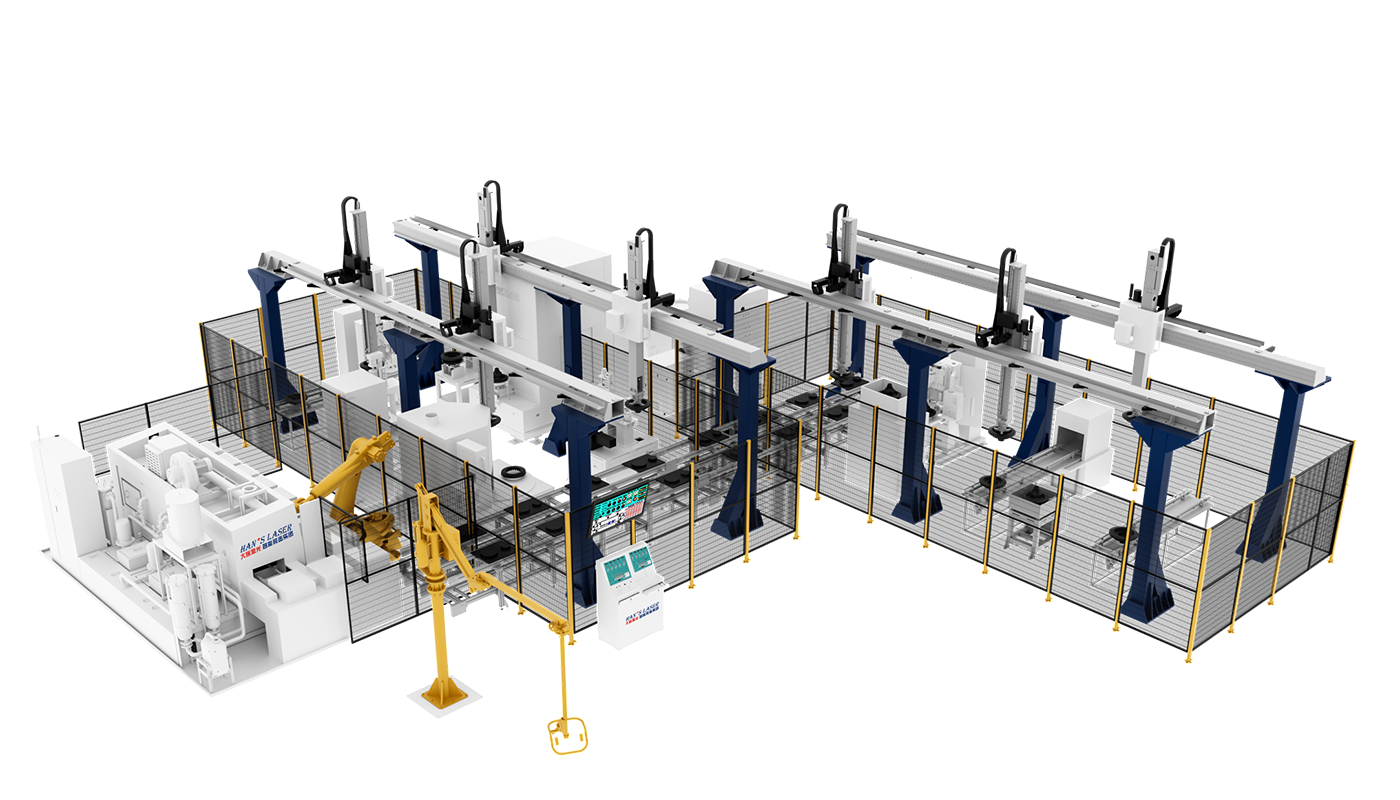

Differential unit automatic assembly line

The differential unit is widely used in passenger and commercial vehicles. The differential unit consists of three main parts: two shell parts and a gear, which contains the cross shaft, planet wheel and so on.

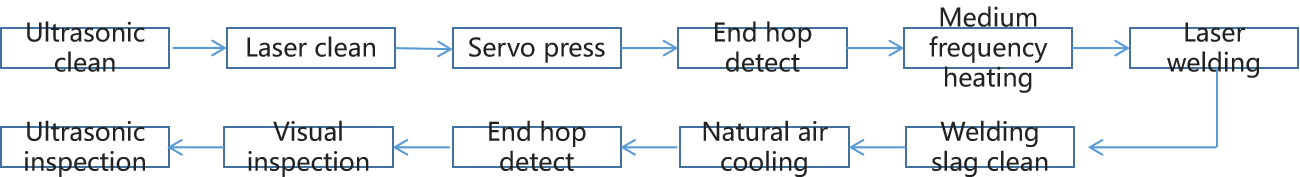

Automatic assembly line is mainly composed of ultrasonic cleaner, loading and unloading robot, Hans high power laser cleaning machine, servo pressing equipment, end hop detection device, medium frequency induction heating equipment, laser welding equipment, welding slag cleaning equipment, natural air cooling, ultrasonic inspection, drying, end hop detection, control and monitor system, product traceability system, laser special smoke purifier, cooling installation and so on.

Line production capacity: 125 s/piece.

Small laser welding deformation, fast speed, ensure tolerance.

Replace the traditional bolt welding process, save bolts, and materials, reduce weight.

Adopt the welding wire researched and developed by Hans, laser wire filling welding solve the problem of pores and cracks.

The differential unit of passenger and commercial vehicles welding process, product processing diameter: 200mm-600mm, weld penetration: 4mm-10mm.

The production line realizes the laser wire filling welding of differential shell and ring gear, completes the welding of differential shell QT400, QT500, 40Cr, ring gear 20CrMnTi and other materials welding.

Realize fully automatic assembly, welding, detection and other functions, compatible across multiple products, high degree of flexibility, achieve fast switching fixture, product traceability.